Factory Automation Solutions

We are a leading distributor, trader and supplier of Factory Automation Solutions such as Scada Systems, Machine Reconditioning, Production Monitoring Systems and Customized Control Panels.

Production Monitoring Systems

It is a complete system linked to optical sensors on your production line which allows monitoring of production performance both on and off the shop floor.

The system is very flexible and comes in many guises but essentially it works as follows:

- For each production line the number of units which should have been made is calculated on an on going basis (The TARGET).

- Each time a unit is produced by your production line it is registered by the system (The ACTUAL).

- From the target and actual production figures the efficiency of the production line is calculated (The EFFICIENCY).

- All the figures are displayed on either (or both) individual line display(s) or a scoreboard showing all the lines on a single display.

- The whole system is controlled by either a central PC or local controller and allows complete pre programming of shift patterns and production rates.

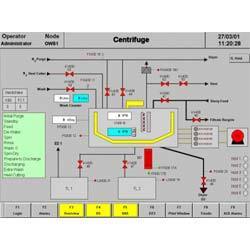

Scada Systems

SCADA or Supervisory Control And Data Acquisition is a large scale control system for automated industrial processes like municipal water supplies, power generation, steel manufacturing, gas and oil pipelines etc. SCADA also has applications in large scale experimental facilities like those used in nuclear fusion. SCADA systems monitor and control these operations by gathering data from sensors at the facility or remote station and then sending it to a central computer system that manages the operations using this information.

Features:

A full fledged SCADA system is made up of signal hardware for input/ output, networks, control equipment, user interface (sometimes called the Human-Machine Interface or HMI), communication equipment and the software to go with it all.